Aerospace & Defense

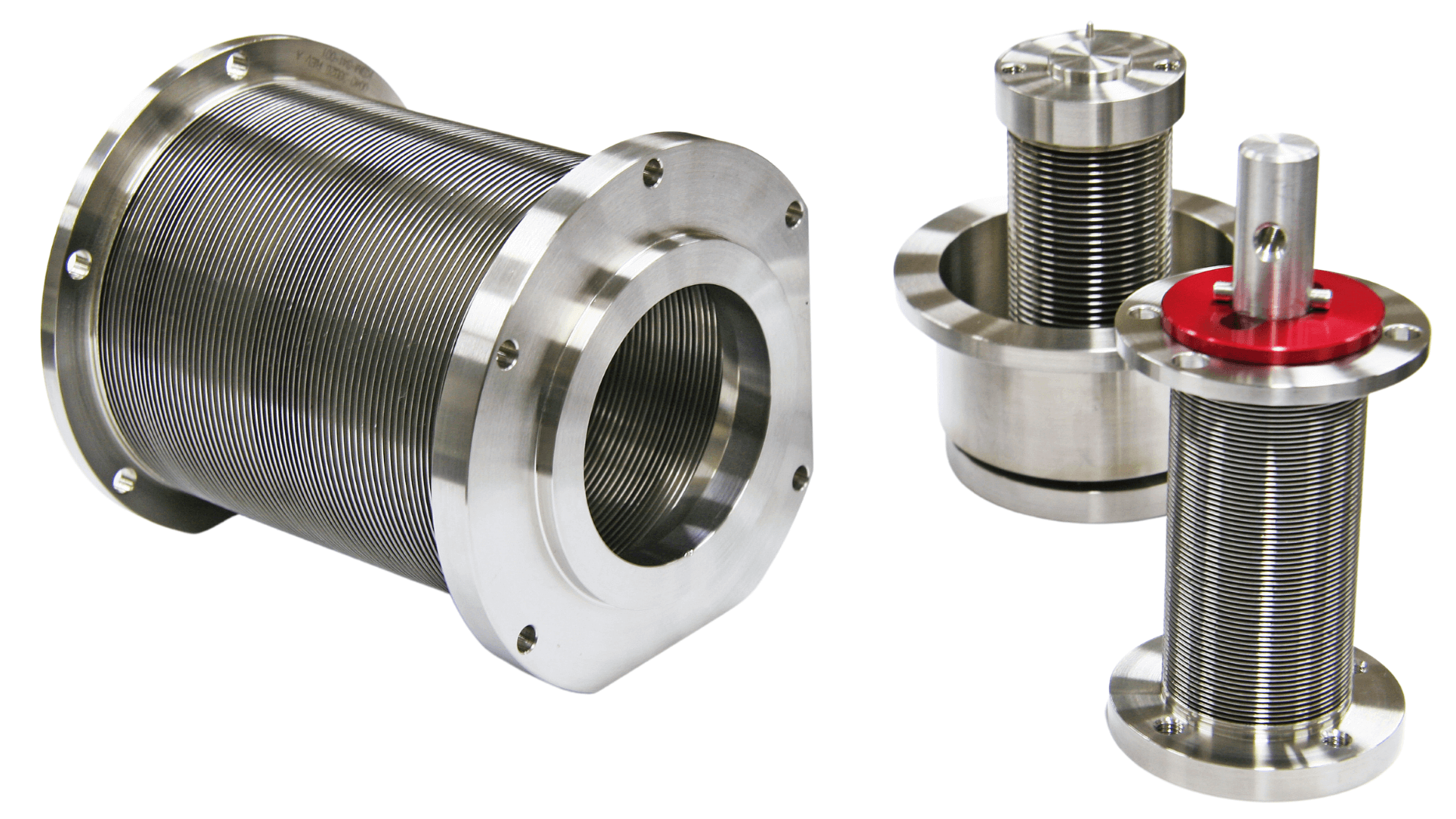

Heat and Corrosion resistant Welded Bellows for Aerospace & Defense

THE MARKET TREND

The largest % spending increases should be in the Space sector by government and private companies.

Supply chains will be stressed due to raw material availability, possible transportation bottlenecks and concerns on material price increases.

WHERE ARE KSM Edge Welded Metal Bellows USED?

From Volume Compensators in oil cooled electronic chassis- to Face Seals on APUs; to Pressure Sensing Bellows regulating Fuel Systems..: KSM can provide precision-built assemblies from a wide variety of high strength and high temperature alloys.

APPLICATIONS INCLUDE:

- Aneroids

- Flexible Connectors

- Reservoirs

- Accumulators

- Mating Seal Rotors

- Temperature Sensors

- Couplings

- Mechanical Face Seals

- Vibration Dampeners

- Expansion Joints

- Pressure Sensors

- Volume Compensators

WHAT ARE THE KSM ADVANTAGES?

- CLEANLINESS: KSM offers the highest levels of product cleanliness and purity; starting with our Automated Component Parts Cleaning Lines to our Class 6 [1000] Clean Room for Welding & Assembly and Class 5 [100] Final Inspection and Packaging area.

- BELLOWS MATERIAL: KSM maintains full traceability and spec. compliance on all materials for bellows and related components. Typical alloys are: AM-350® SST, Inconel® 625, Inconel® 718, Haynes® 242 and Titanium GR2. (The most common DEFENSE materials are high-temp or corrosive [ie. Marine - SALT] resistant, and light weight for critical flight machinery).

- VACUUM HEAT TREAT and other specialty material treatments AVAILABLE for specialty alloys.

- CAPACITY: Production Capacity from the world’s largest edge welded fabrication site and Clean Room can meet your needs from prototypes to high volume.

- LOGISTICS: KSM regularly ships to over 50 countries around the world and maintains large climate-controlled warehouse for all raw materials, with sufficient stocking of popular alloys.

- SUPPORT: KSM maintains a fully equipped Metrology Lab for weld/material evaluation plus and LCP, APC & ICT-MS cleanliness/purity verification plus Testing Lab for force, pressure and life testing.

- RISK-MITIGATION: Check out our MFG OPERATIONS page to learn more about our extensive BCP (Business Continuity Plan) considerations.