Vacuum Research & Development

Custom Welded Bellows for R&D Labs, Universities, Vacuum Chamber Equipment Manufacturers and more...

The Vacuum Equipment / R&D Laboratory marketplace includes:

- R&D Laboratories

- Vacuum Equipment OEMs

- Analytical Equipment OEMs

Due to ramp-up in Semiconductor Manufacturing, Vacuum Valves used on these tools have seen a dramatic rise in volume.

WHERE ARE KSM Edge Welded Metal Bellows USED?

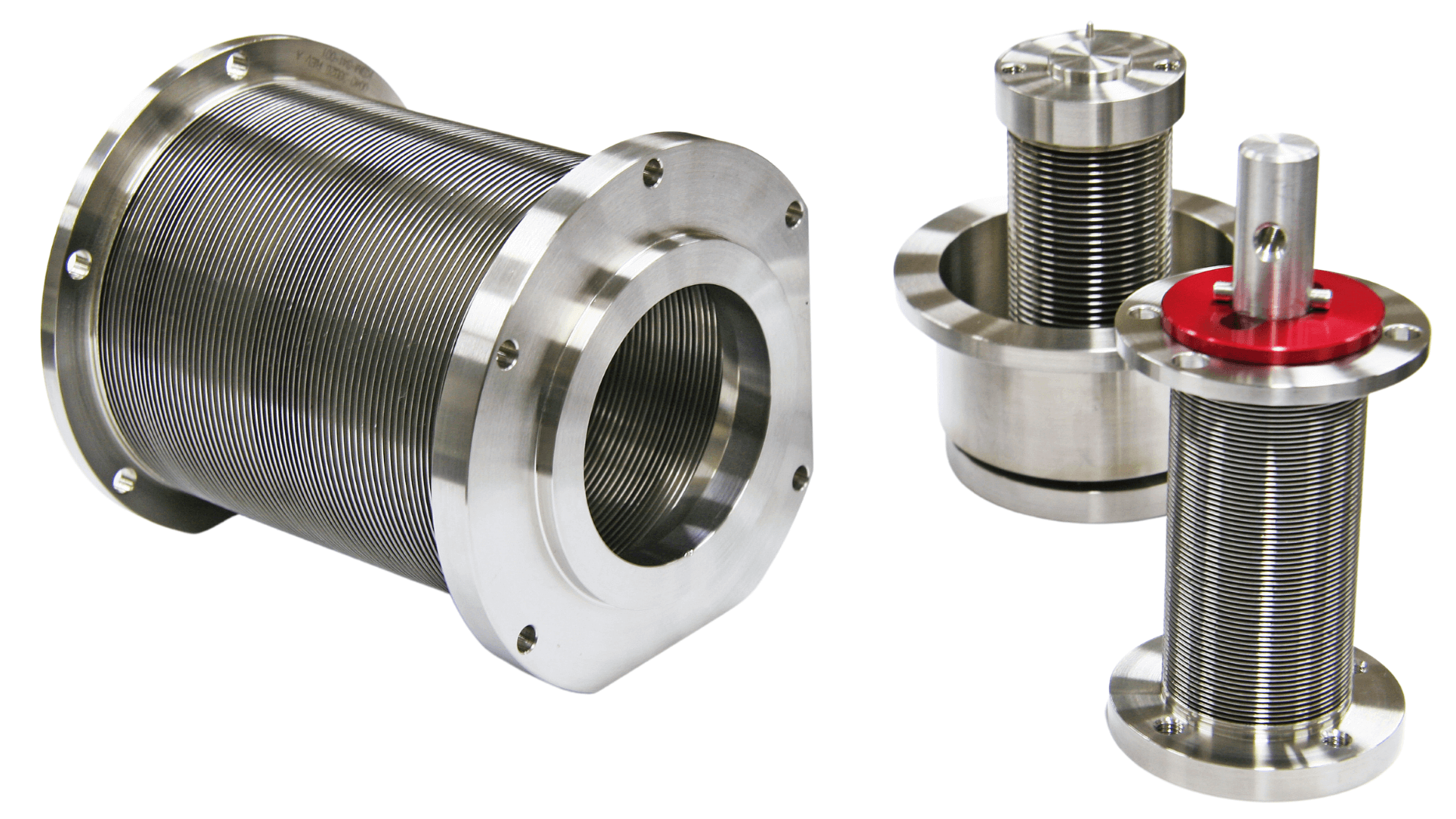

Edge Welded Metal Bellows for Vacuum / R&D Market equipment are historically some of the most fundamental and original applications.

Although many applications have been around for a long time, requirements have evolved to demand better reliability, higher cycle lifetimes, and far cleaner assemblies.

Depending on magnetic permeability requirements, most bellows are 316L SST, 347 SST, or AM350® SST. 316L SST and 347 SST work better in low cryogenic applications; but AM-350® SST, although slightly magnetic, is preferred for its higher strength, where cycle life is critical. Now, many of the Vacuum Valve OEMs specify Inconel® 625 or other more corrosion-resistant alloys for Semiconductor tools environments.

APPLICATIONS INCLUDE:

- Beamline Bellows

- Gimbal Load Locks

- Rotary Feedthroughs

- Cryostat Bellows

- Linear Feedthroughs

- Valve Seals, Linear

- Expansion Joints

- Manipulator, X-Y-Z

- Vibration Damper

- Foreline Connector

- Port Aligners

- Wobble Sticks

- Quartz Crystal

WHAT ARE THE KSM ADVANTAGES?

- CLEANLINESS: KSM offers the highest levels of product cleanliness and purity; starting with our Automated Component Parts Cleaning Lines to our Class 6 [1000] Clean Room for Welding & Assembly and Class 5 [100] Final Inspection and Packaging area.

- BELLOWS SIZES: KSM has an extensive list of existing tooling [Bellows Dies] from 9.5 (0.375”) to 950 mm (37.5”) OD. KSM offers bellows that are compatible with all the standard industry CF, KF & ISO Flanges.

- MATERIALS: Most R&D Beamlines require the use of magnetic permeability materials with 304L, 316L & 347 SST the most popular. KSM maintains large inventories of these alloys for bellows and machined parts, with fully traceable certifications.

- END FLANGE SPECIAL PROCESSING: To improve cleanliness and surface finish on machined surfaces; KSM maintains an Electro-polishing line for hardware/machined components when desired by customers.

- CAPACITY: Production Capacity from the world’s largest edge welded fabrication site and Clean Room can meet your needs from prototypes to high volume production.

- LOGISTICS: KSM regularly ships to over 50 countries around the world and maintains a large climate-controlled warehouse for all raw materials – with full component traceability

- SUPPORT: KSM maintains a fully equipped Metrology Lab for component evaluation and cleanliness verification. On top of housing their own separate R&D Testing Lab on campus.